Introduction

Explore the nuanced realm of machete production in China, with a special emphasis on the meticulous blade sharpening techniques. Understanding these varied methods for achieving precision and sharpness provides a profound insight into the craftsmanship and quality involved. At Gear Machete, our commitment ensures that each blade excels in machete sharpening techniques, meeting the highest standards of excellence.

The Significance of Blade Sharpening

After undergoing meticulous heat treatment and polishing, Gear Machete’s blades are crafted to achieve the best balance of hardness, flexibility, and wear resistance. These characteristics are essential for a machete, ensuring it performs effectively in demanding cutting tasks without compromising its structural integrity.

Blade sharpening is a crucial step in machete production. The sharpened length typically covers about four-fifths of the blade’s total length. The section from 5cm to 18cm from the tip is the most frequently used for cutting. This makes it imperative to ensure this part of the blade is exceptionally sharp and durable, providing reliable performance for cutting smaller branches, shrubs, and agricultural plants.

Ensuring Performance During Use

For a machete to be effective, it must maintain its edge during use. The blade must withstand tough conditions without rolling or chipping. This performance requirement highlights the importance of effective heat treatment and precise sharpening techniques. At Gear Machete, we ensure our blades meet these high standards, providing you with tools that remain sharp and dependable through extensive use.

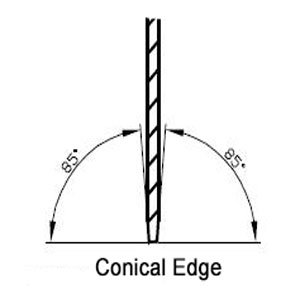

Conical Edge Technique

Gear Machete employs a conical edge sharpening technique, a method that demands precision and skill. Whether performed by hand or machine, the conical edge requires a thorough understanding of the sharpening angle. This ensures the blade’s sharpness and reliability, crucial for its cutting performance. Our workers are trained to meticulously control the sharpening angle, delivering blades that meet our rigorous quality standards.

Delivering Excellence to Customers

By adhering to these rigorous processes and standards, Gear Machete ensures that every machete delivered to our customers is of superior quality. Our blades are sharp, reliable, and capable of providing the best cutting performance. Trust in Gear Machete for tools that combine traditional craftsmanship with modern precision, ensuring excellence in every cut.

Introduction to Gear Machete’s Blade Sharpening Techniques

To ensure that every Gear Machete blade achieves exceptional sharpness and durability, our factory in China employs three distinct sharpening methods. Each technique offers unique advantages, ensuring that the blades perform excellently in various cutting scenarios. Let’s dive into these three sharpening techniques and their specific characteristics.

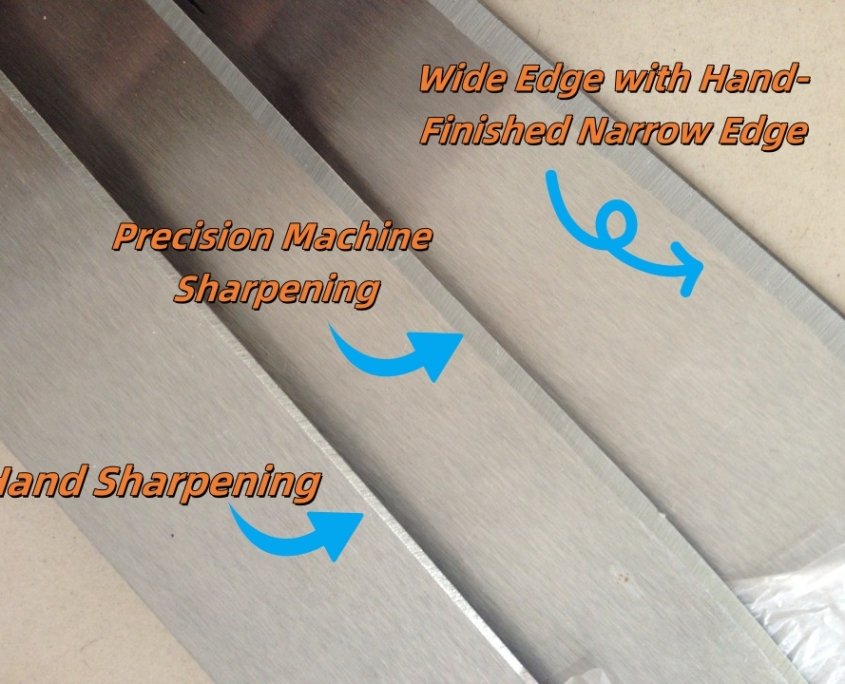

1. Hand Sharpening

Hand sharpening involves a skilled worker manually sharpening each blade on a high-speed grinding wheel. This method results in a blade edge approximately 2mm wide. The consistency and smoothness of the edge rely heavily on the worker’s experience and technique. While this method requires a high level of skill, it produces a unique edge quality, ensuring that every blade has a personalized touch.

2. Precision Machine Sharpening

Precision machine sharpening creates what is known as a sharp edge. The edge width ranges from 2-3mm. This method uses a stroke-based sharpening machine, where the sharpening starts according to the blade’s length and specific mold settings. By controlling the grinding wheel’s angle, we achieve precise edge angles, minimal deviations, and consistent smoothness. This method ensures that every blade is exceptionally sharp, providing the cutting efficiency you need for demanding tasks.

3. Wide Edge with Hand-Finished Narrow Edge

This hybrid method combines the benefits of machine and hand sharpening. Initially, a stroke-based sharpening machine forms a wide edge, ranging from 3-5cm. Although this edge is not very sharp, a subsequent hand sharpening step narrows the edge to approximately 2mm. This dual-step process results in a blade that not only looks impressive with its wide edge but also gains significant sharpness. Additionally, this method makes re-sharpening the blade easier in the future, ensuring long-lasting performance.

Conclusion:

Understanding these sharpening techniques gives you insights into why Gear Machete’s blades are a cut above the rest. Each method, from the artisanal hand sharpening to the precision of machine sharpening, ensures you receive a high-quality, durable, and sharp machete. For more information on our products and to see the full production process in action, watch our detailed video.