Here’s a detailed comparison between 65Mn, 50Mn (Chinese standards), and SAE 1070, SAE 1050 (American standards):

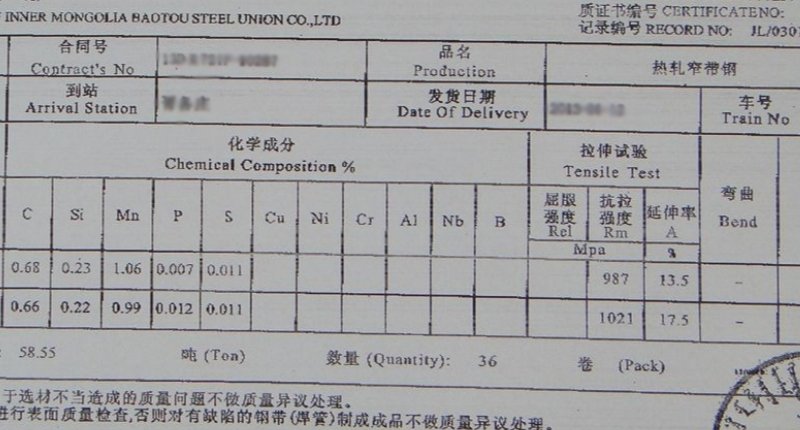

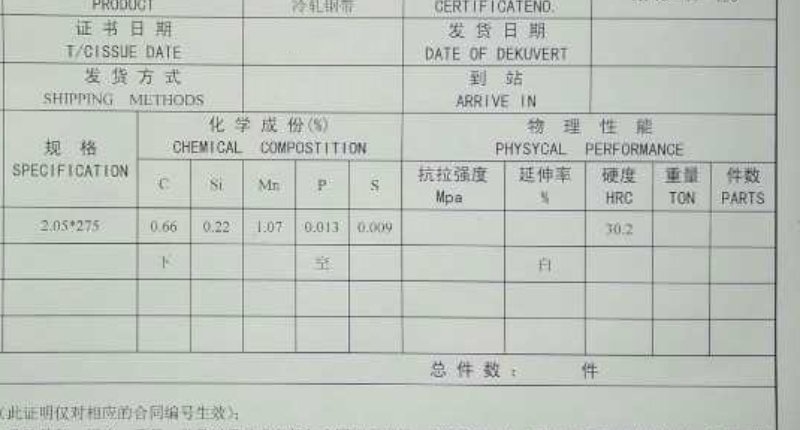

🔍 1. Chemical Composition Comparison

| Element |

65Mn (GB/T 1222) |

SAE 1070 |

50Mn (GB/T 699) |

SAE 1050 |

| Carbon (C) |

0.62 – 0.70% |

0.67 – 0.75% |

0.48 – 0.56% |

0.47 – 0.55% |

| Silicon (Si) |

0.17 – 0.37% |

0.17 – 0.37% |

0.17 – 0.37% |

0.15 – 0.35% |

| Manganese (Mn) |

0.90 – 1.20% |

0.50 – 0.80% |

0.70 – 1.00% |

0.60 – 0.90% |

| Phosphorus (P) |

≤0.025% |

≤0.04% |

≤0.025% |

≤0.04% |

| Sulfur (S) |

≤0.020% |

≤0.05% |

≤0.020% |

≤0.05% |

Key Differences:

- 65Mn ≈ SAE 1070, but 65Mn has slightly higher manganese, enhancing wear resistance and toughness.

- 50Mn ≈ SAE 1050, both are medium carbon steels with good toughness and moderate hardness.

- Chinese standards have stricter P & S control, which improves toughness and reduces brittleness.

⚙️ 2. Mechanical Properties (After Heat Treatment)

| Property |

65Mn |

SAE 1070 |

50Mn |

SAE 1050 |

| Hardness (HRC) |

54–58 |

53–58 |

45–52 |

45–52 |

| Toughness |

High (with proper tempering) |

High |

Medium-High |

Medium-High |

| Elasticity (Spring Behavior) |

Excellent |

Good |

Moderate |

Moderate |

| Wear Resistance |

Excellent |

Good |

Moderate |

Moderate |

| Workability |

Moderate |

Moderate |

Good |

Good |

🛠️ 3. Typical Uses

| Application |

65Mn |

SAE 1070 |

50Mn |

SAE 1050 |

| High-performance machetes |

✅ |

✅ |

— |

— |

| Sugarcane knives |

✅ |

✅ |

✅ (lower grade) |

✅ |

| Springs & saw blades |

✅ |

✅ |

❌ |

❌ |

| Shovels, hoes |

— |

— |

✅ |

✅ |

| Automotive springs |

✅ |

✅ |

❌ |

❌ |

| Low-cost cutting tools |

❌ |

❌ |

✅ |

✅ |

🌟 4. Summary of Differences

| Feature |

65Mn / SAE 1070 |

50Mn / SAE 1050 |

| Carbon & Mn content |

Higher |

Lower |

| Hardness potential |

Higher |

Moderate |

| Wear resistance |

Strong |

Normal |

| Elasticity / Springiness |

Excellent |

Moderate |

| Rust tendency |

Higher (needs anti-rust treatment) |

Moderate |

| Best for |

Premium machetes, springs |

Basic tools, entry-level machetes |

✅ Gear Machete’s Selection Recommendation

- 65Mn (≈ SAE 1070): Preferred for high-end machetes, where sharpness retention, toughness, and durability are critical.

- 50Mn (≈ SAE 1050): Used in cost-sensitive markets (e.g., Africa) for standard machetes, hoes, and shovels where toughness matters more than extreme hardness.

If you need, I can prepare a materials datasheet PDF or an Enfold content block for this.